Facilities

Facilities

About Us

Our structured investment plan in recent times has put Keltech at the forefront of manufacturing with regards to our four main specialities : Acoustic Enclosures, Tanks, Over-Head Guards & Cabins and Telecommunications enclosures. We have full control over all manufacturing processes related to the above products

Our competitors may offer one or more elements of our scope but few can provide the full spectrum of linked processes that we can.

Keltech Process 1 : Cutting, materials are cut according to requirements using any one of our numerous Trumpf punches (up to 6mm) or our Trumpf laser (up to 25mm)

Keltech Process 2: Folding/Forming, most parts must next be formed into shape using one of our 8 Trumpf Press brakes

Keltech Process 3: Cellular Welding, Parts consisting of various components are tacked and welded together in individual cells by our coded welders

Keltech Process 4: Five Stage Zinc Phosphate Pretreatment, Parts are then cleaned and chemically treated on our automated plant

Keltech Process 5: Powder/Wet Paint, Parts are coated inline with customer specification

Keltech Process 6: Kitted Parts are assembled into a complete unit before being packed for dispatch

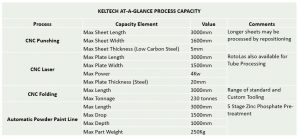

Keltech at-a-glance process capacity

See capacity list